You will need to create a 3D model of each part of your joint set out in one template file.

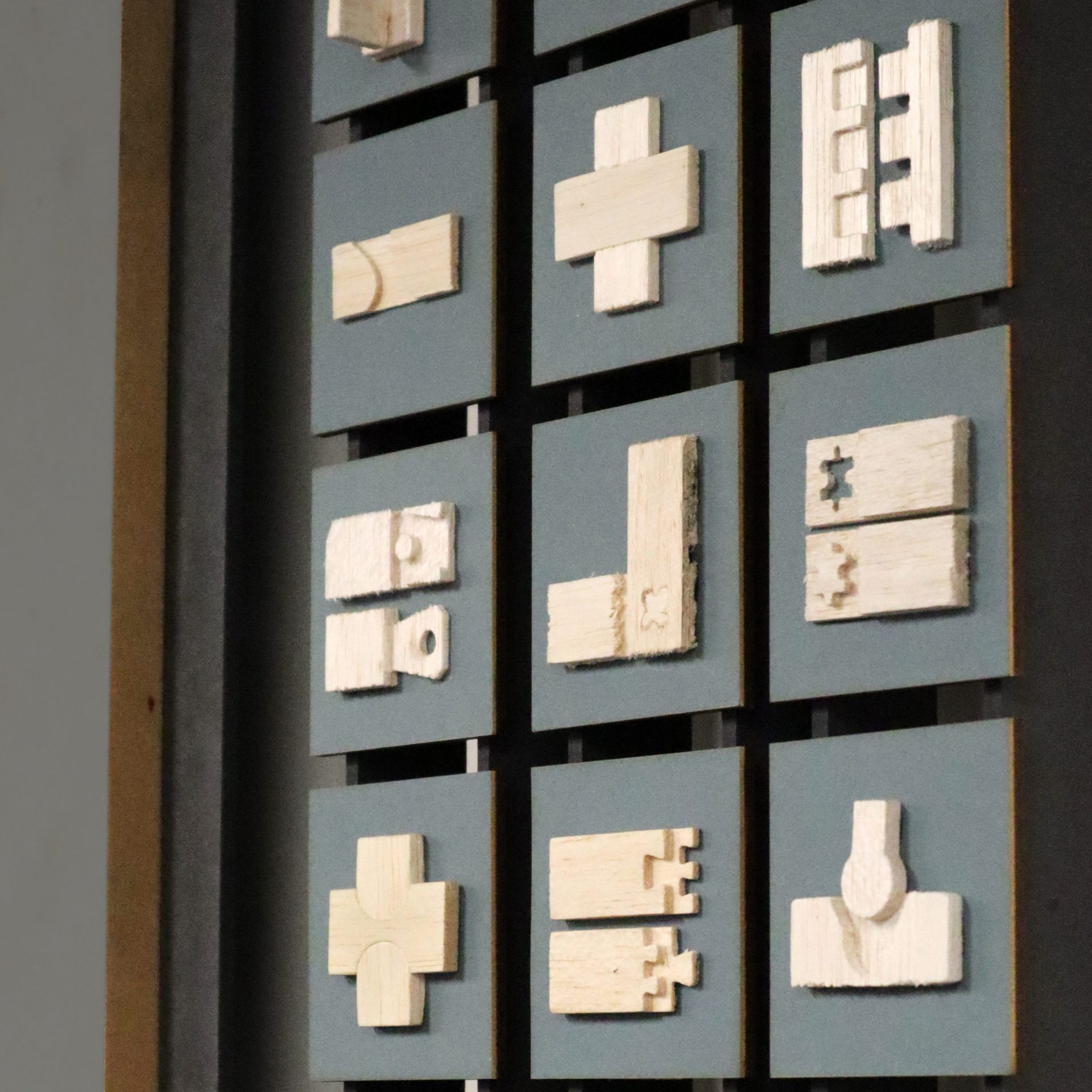

Above is a photograph of past examples. This should give you an idea of what is expected.

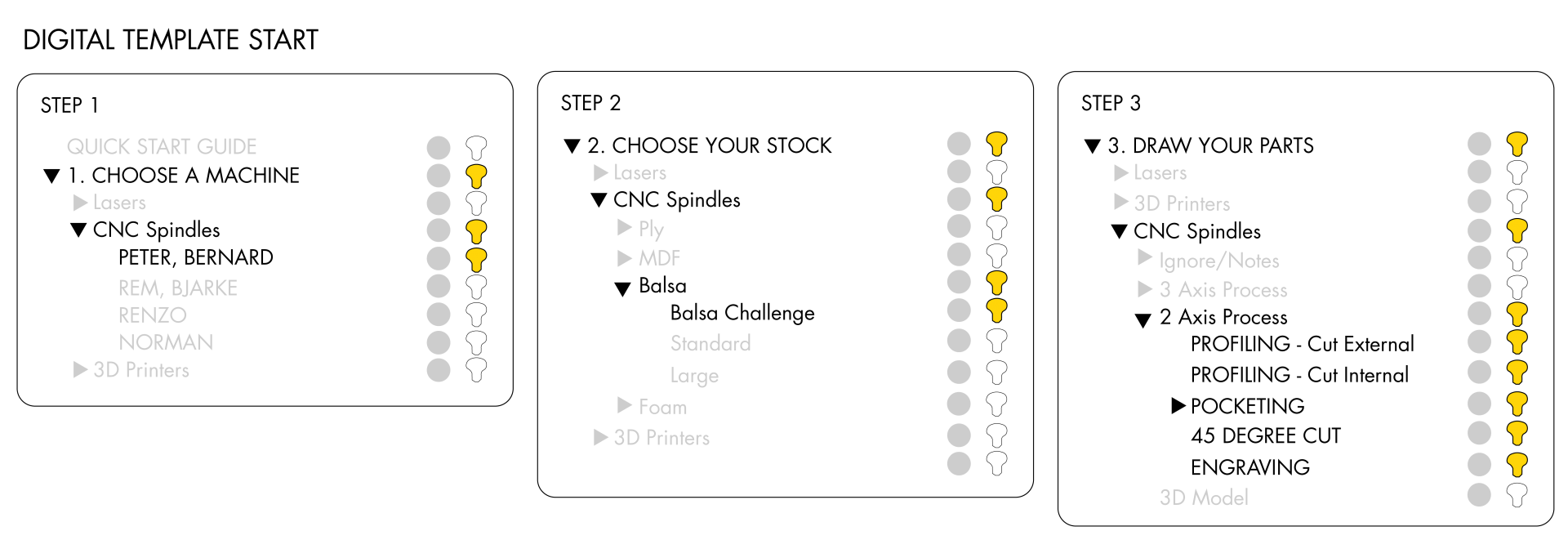

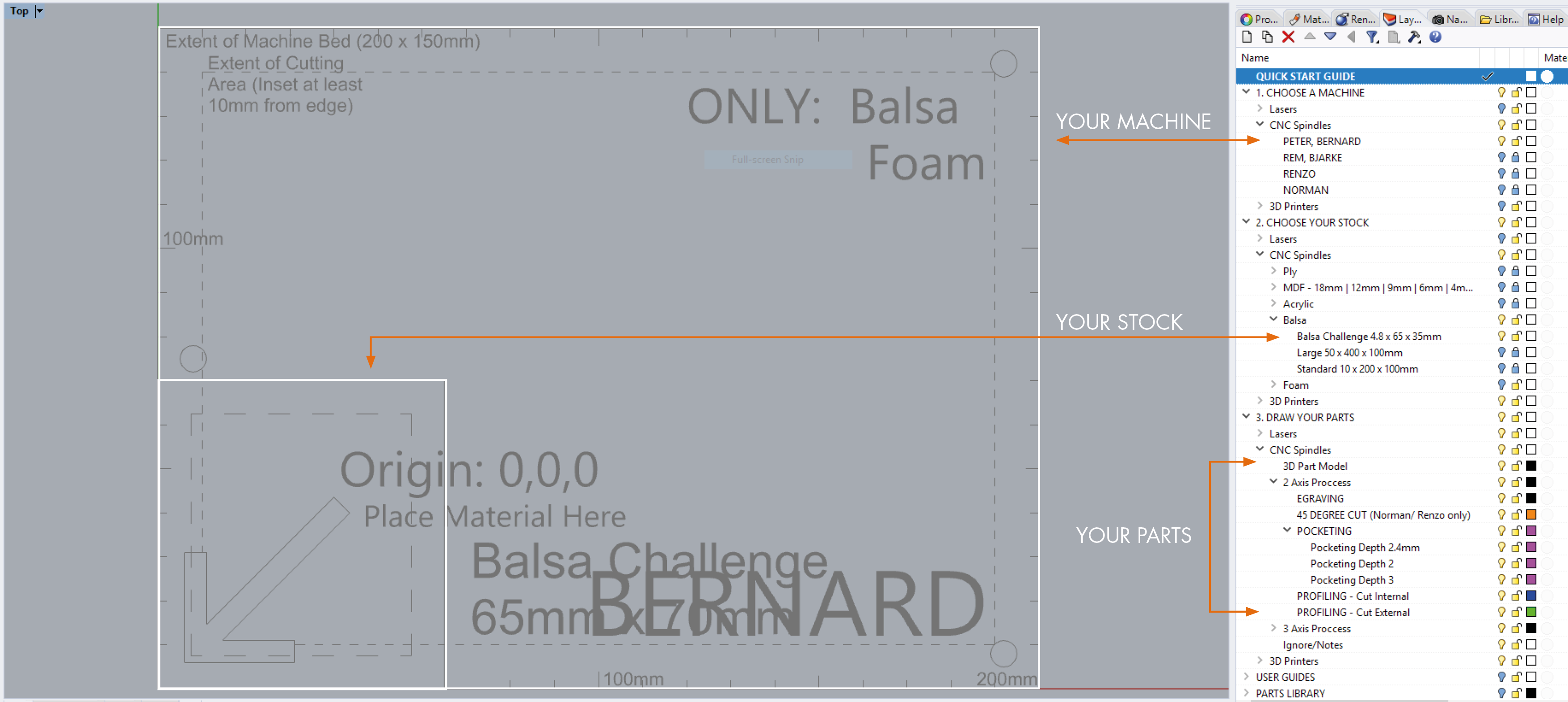

USING THE DIGITAL MACHINE TEMPLATE:

Download the template file from the right hand column.

The Template file is extremely rich and includes a host of information in the 'User Guide' layer. It also represents the sizes of the beds on our different machines and the stock material sizes.

GOLDEN RULES:

• Always work from the latest Template file, which you can download from the "Template" button on the right hand side.

• Do not change the file, apart from adding your own drawing into the appropriate layers

• Do your drafting in a separate Rhino file or whatever other software you like, and then copy/import this into the Rhino Template

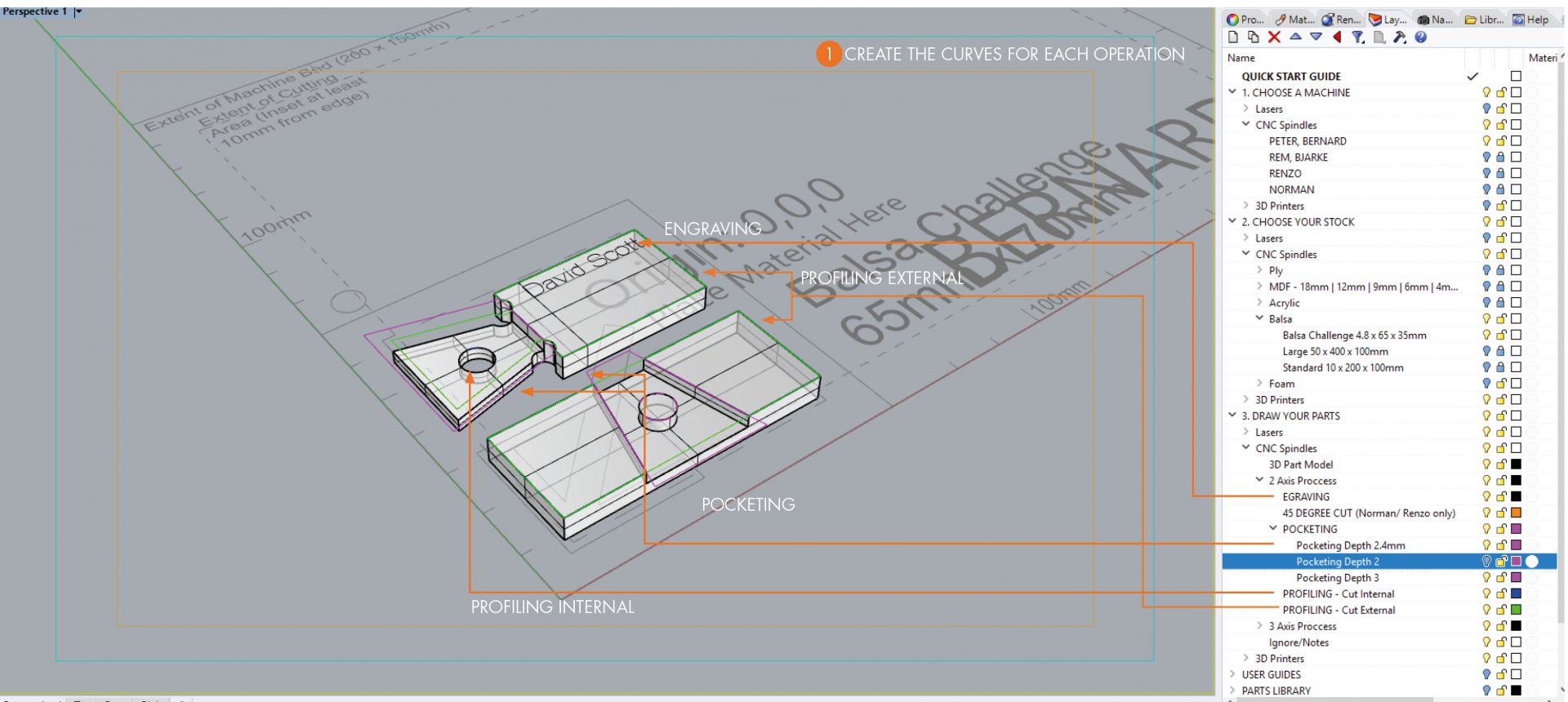

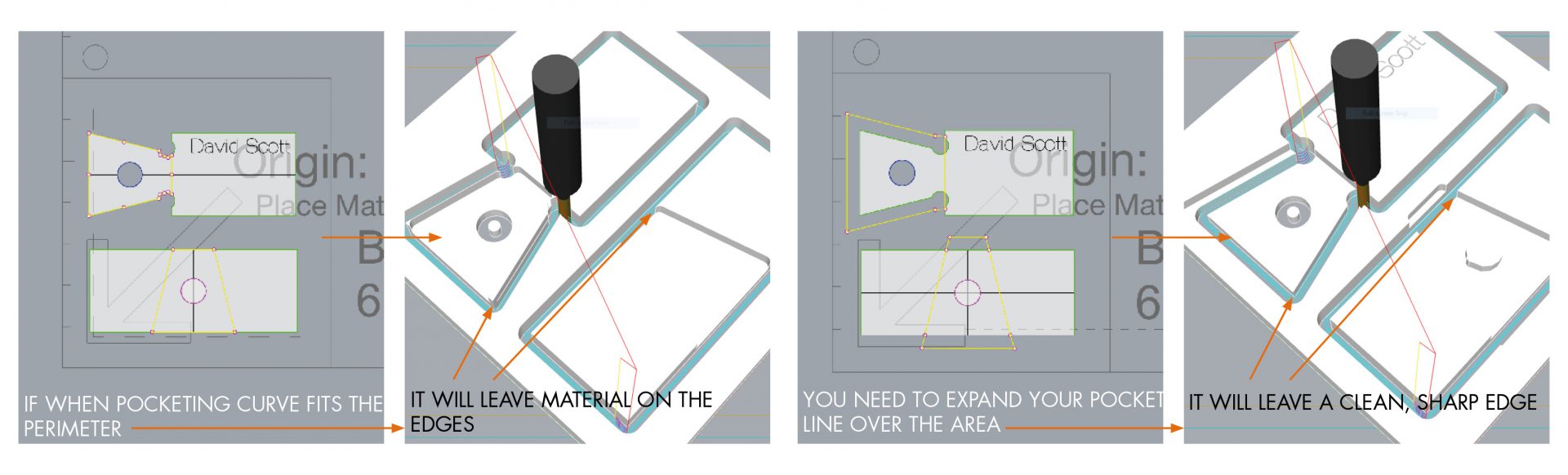

In the layers that you place your work you have seen there are 2 axis operations and 3 axis operations. 2 axis operations require curves while the 3 axis operations require surfaces. In the template file under USER GUIDES you will find more information regarding each operation.

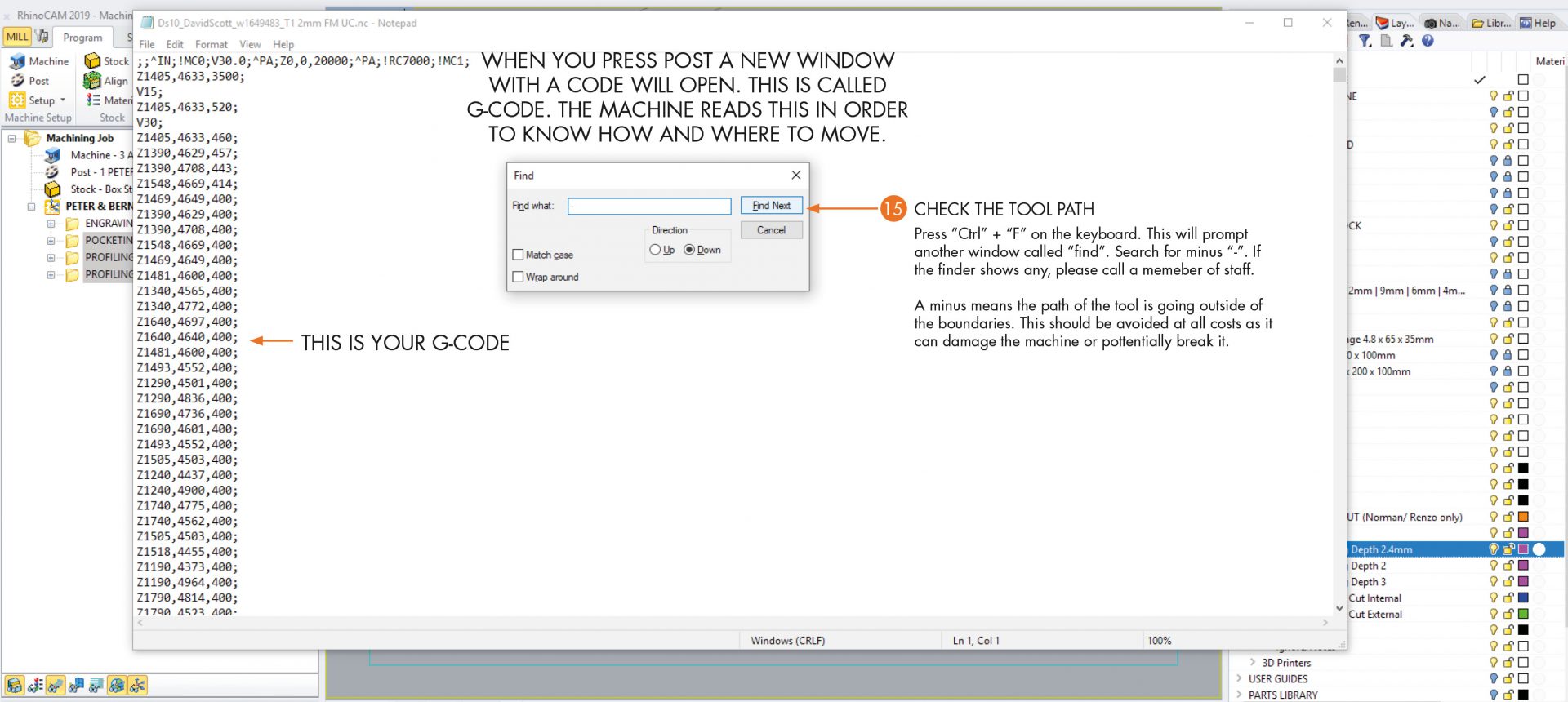

Below is a screen grab of what you should have.

PREPARE YOUR FILE IN THE CAM LAB:

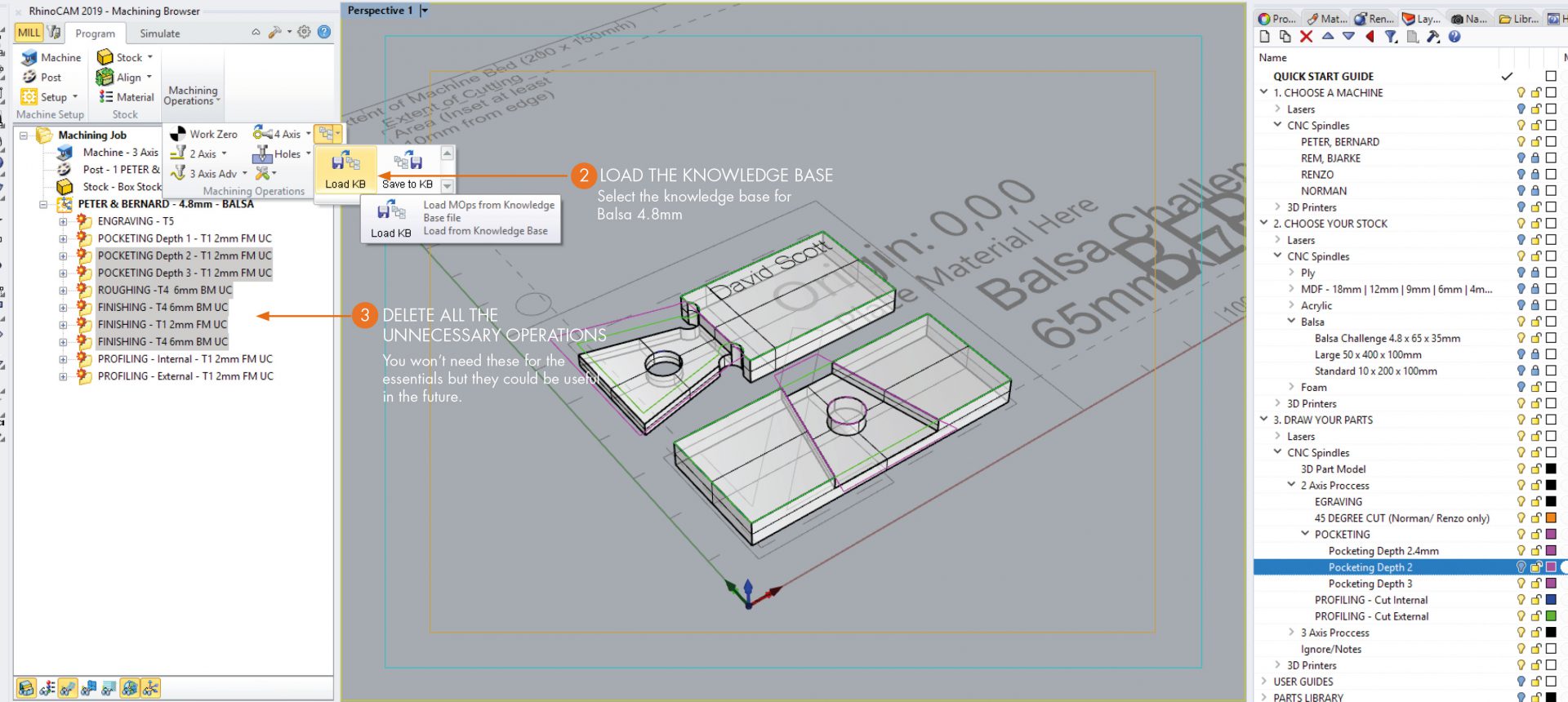

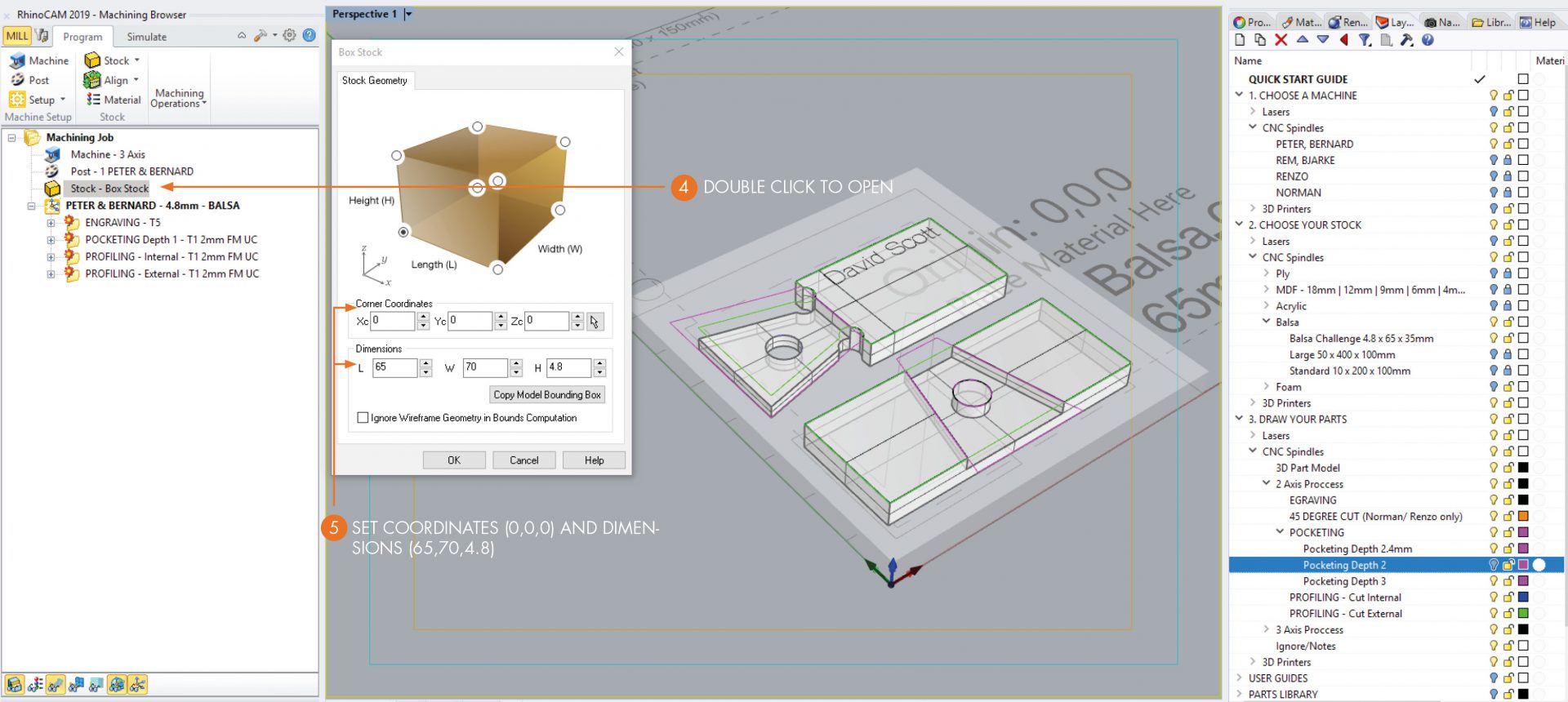

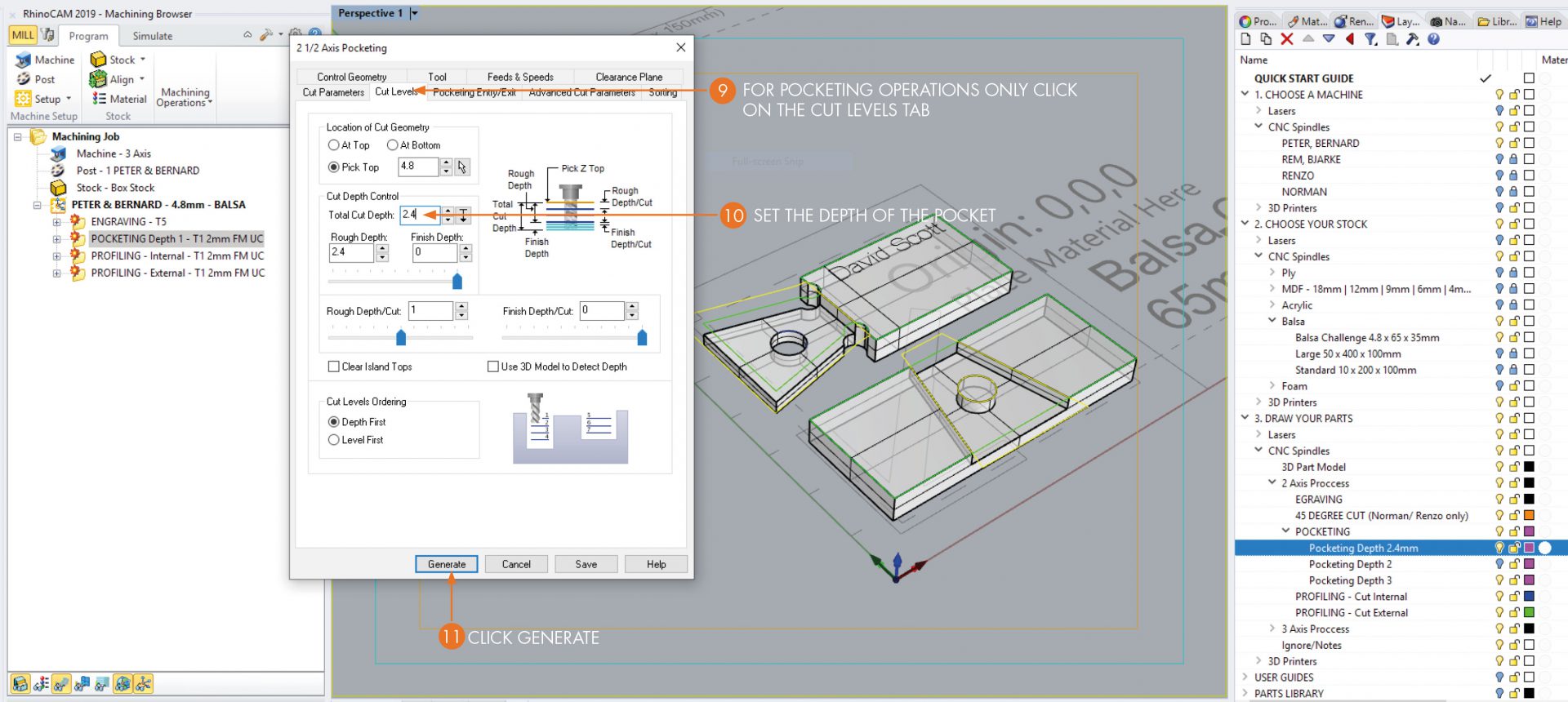

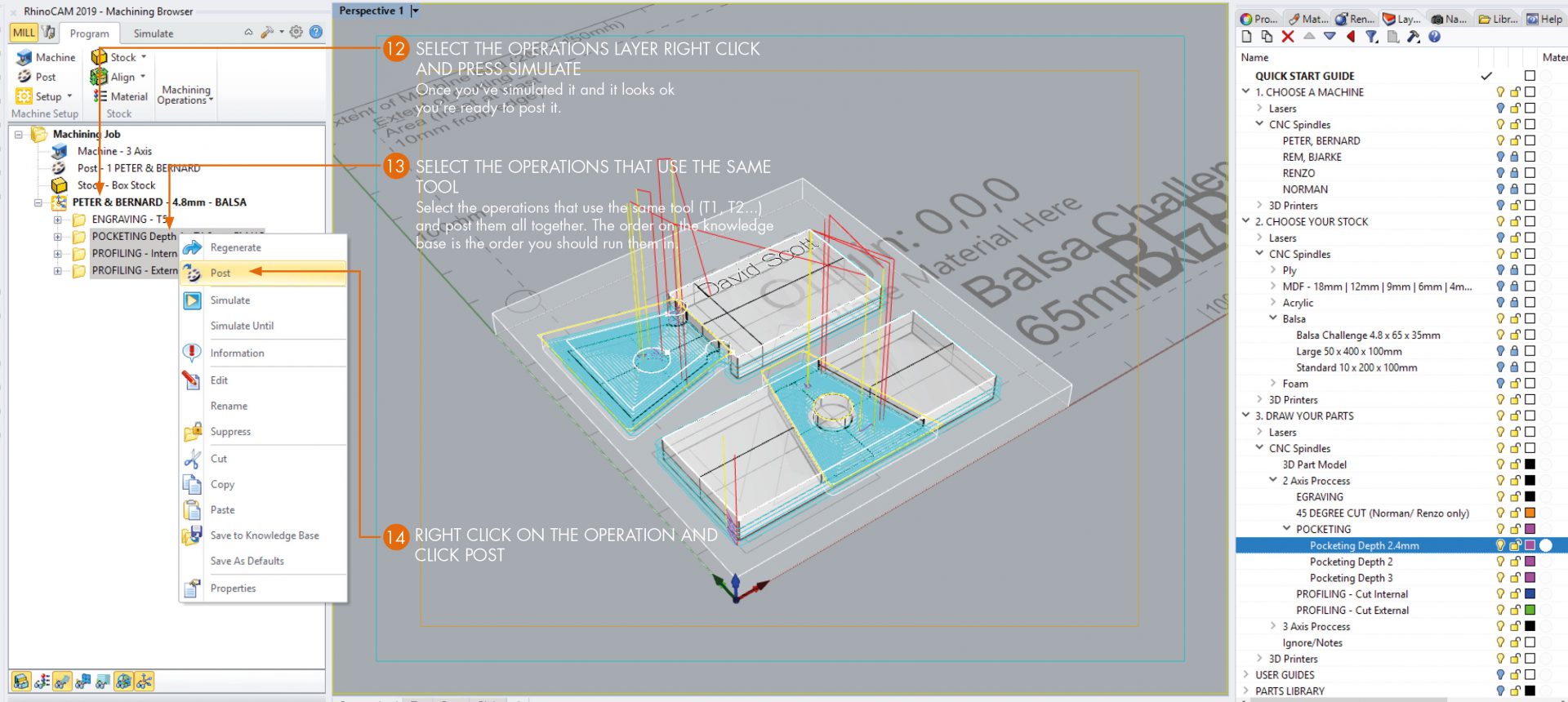

Below you will see a step by step guide on how to use the template and get your file ready. Before you can program your file you will need to download the correct Knowledge Base for your material from the right-hand-side.

You will then need to come to the CAM Lab to use RhinoCAM. Programming your file in the CAM Lab is only one part of your essentials, but it is NOT the whole CNC Essentials.

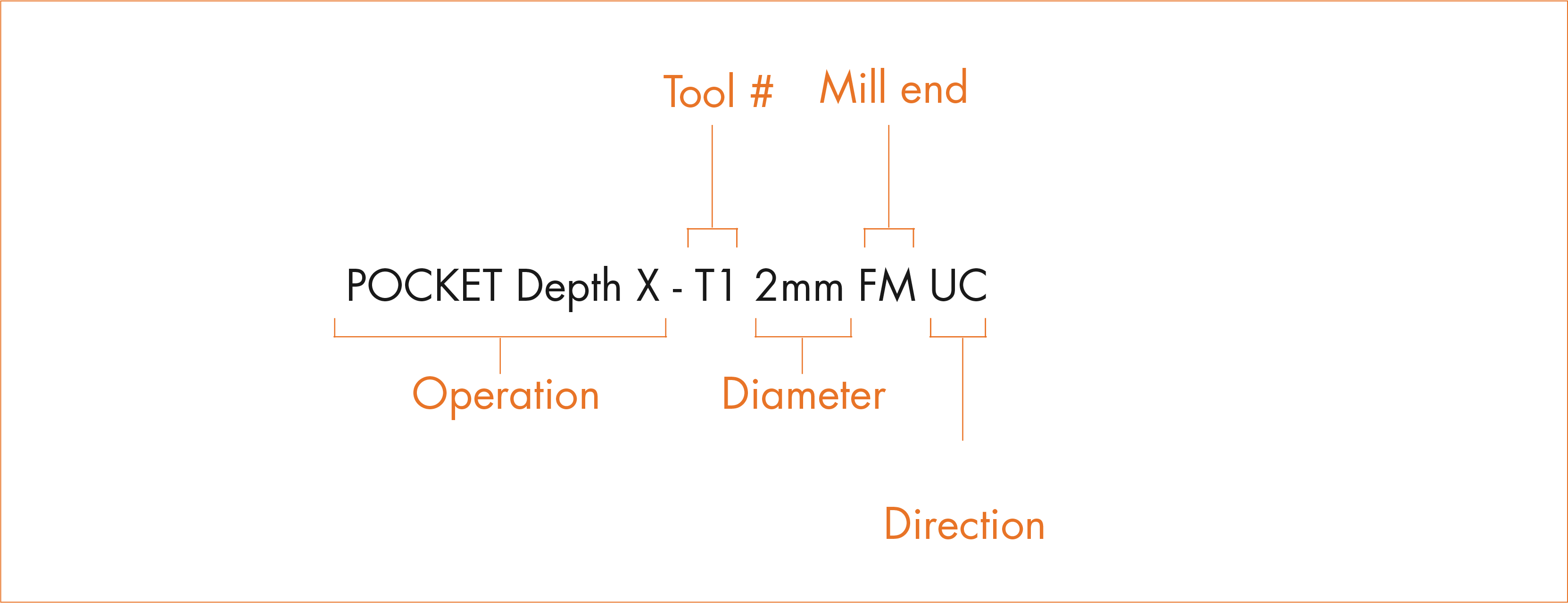

Save your file following our naming convention:

DSxx_W1234567_name_CNC_material_XXmm_TX

(example DS23_w1942781_DavidScott_CNC_Balsa_4.8mm_T1)

ANATOMY OF A KNOWLEDGE BASE:

PLEASE USE THE ARROWS ON THE SIDES TO NAVIGATE THE GALLERY AND SEE ALL THE STEPS TO PROGRAM YOUR FILE:

REMEMBER THAT THE EXAMPLE ABOVE IS JUST THAT, AN EXAMPLE. YOU NEED TO DESIGN YOUR OWN JOINT! NOT JUST COPY THE GEOMETRY YOU SEE ABOVE.

The Checklist below is only a resource to help you create a suitable file for CNC machining.