NAMES

DANIEL, PETER, BERNARD, REM, BJARKE, RENZO AND NORMAN

LOCATION

CNC LAB

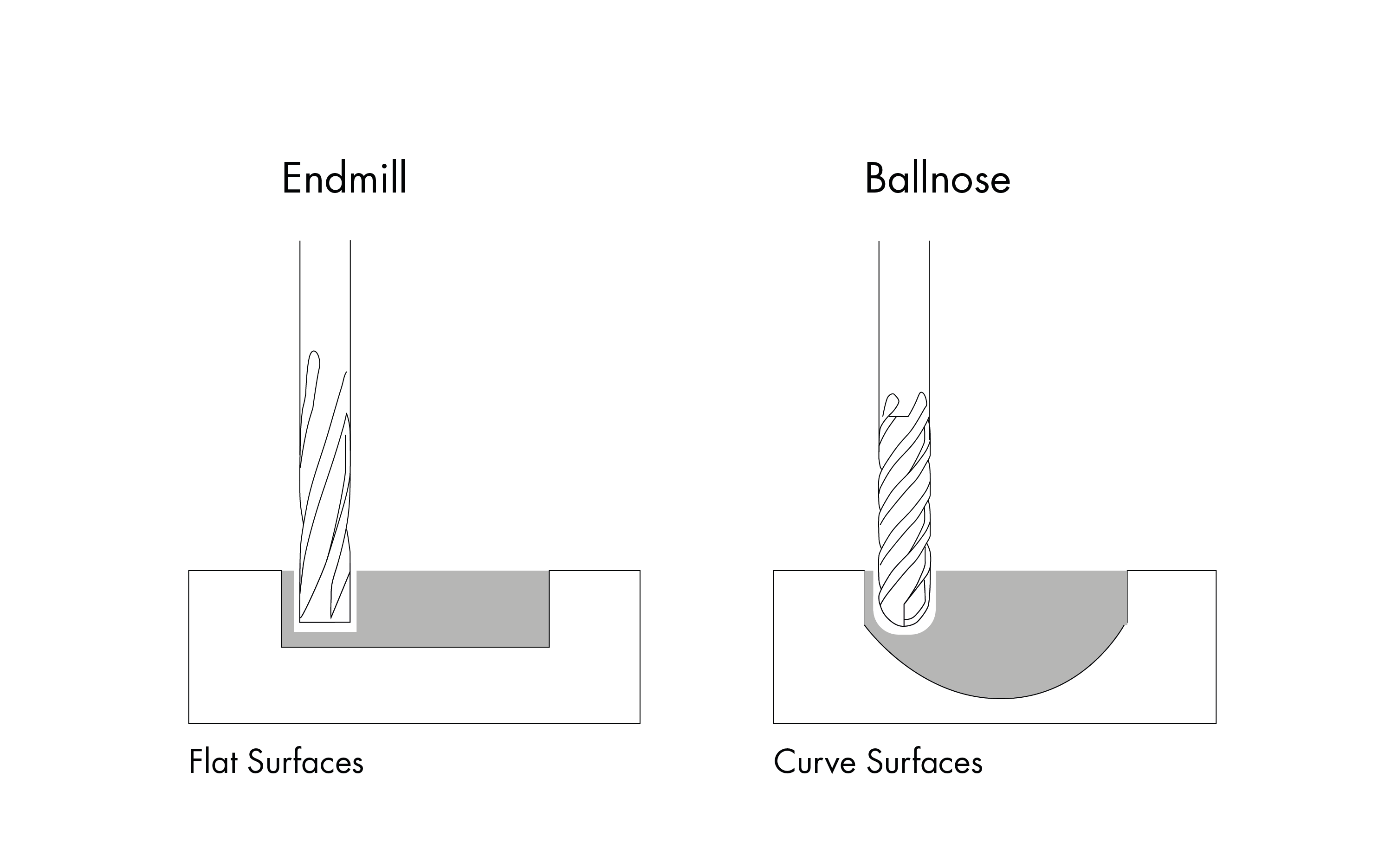

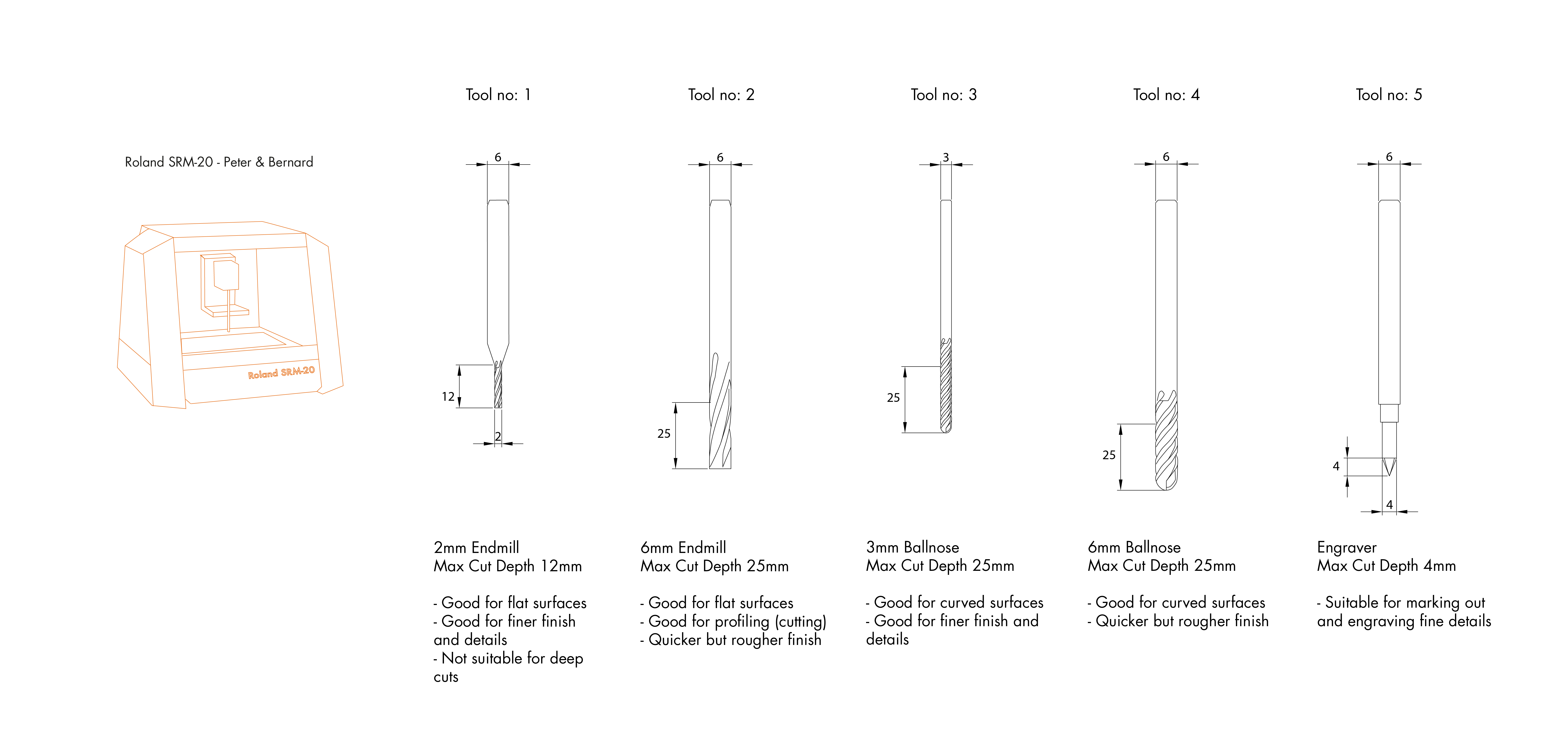

BASIC OPERATIONS

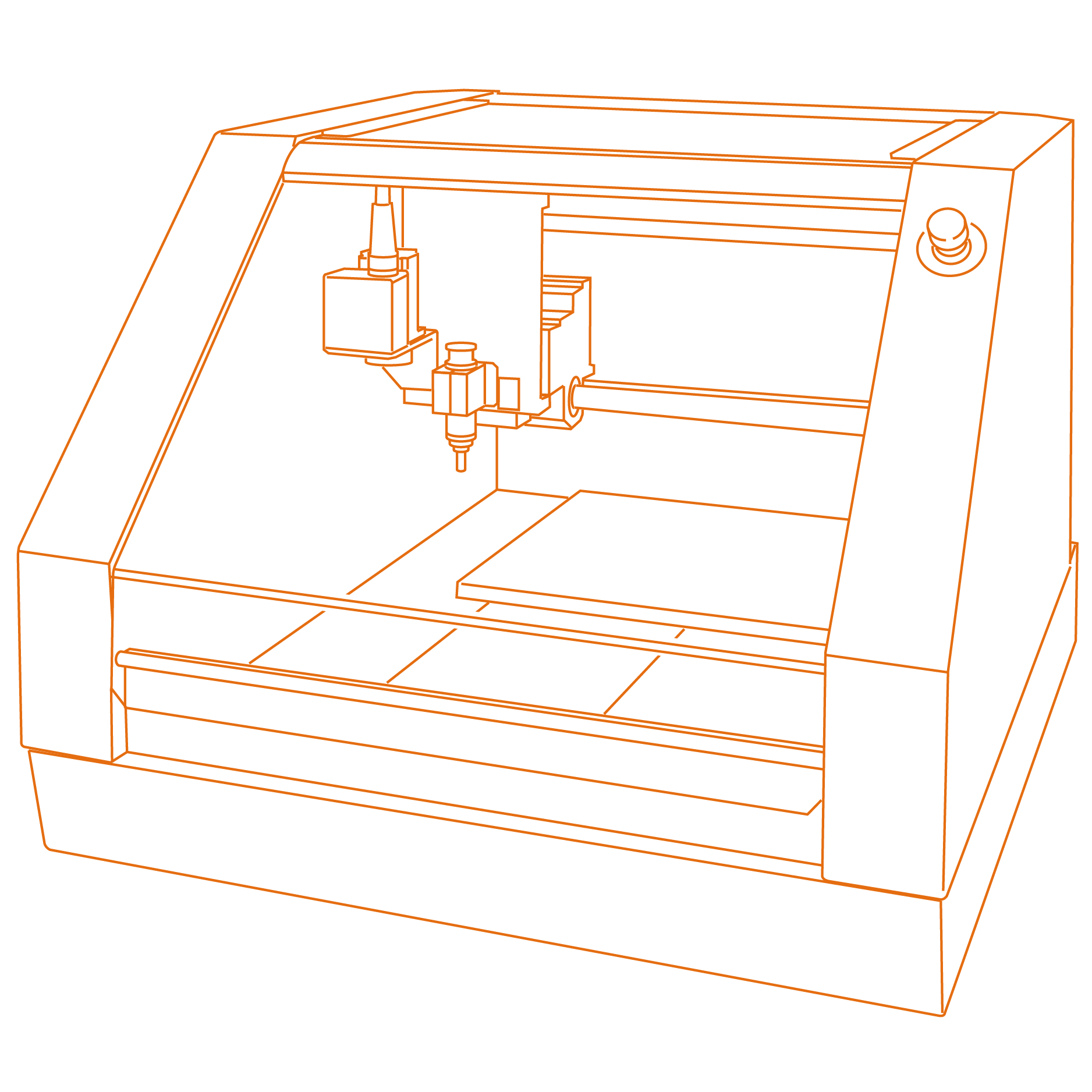

ROUTER

SIZES

200x150x40mm (PETER, BERNARD, DANIEL)

290x390x50mm (REM, BJARKE)

1220x1220x50mm (RENZO)

1220x2440x50mm (NORMAN)

MANDATORY REQUIREMENTS

COMPLETION OF CNC ESSENTIALS

MATERIALS

ONLY USE MATERIALS SUPPLIED BY THE LAB

HAZARDS

COLLISION

FIRE

HARMFUL INHALATION

REMEMBER

ALWAYS WATCH THE MACHINE

CHECK EXTRACTION