1. Complete CNC Essentials

Complete your CNC Essentials. Without this your cannot move farward and use the machines.

2. Create your geometry to machine.

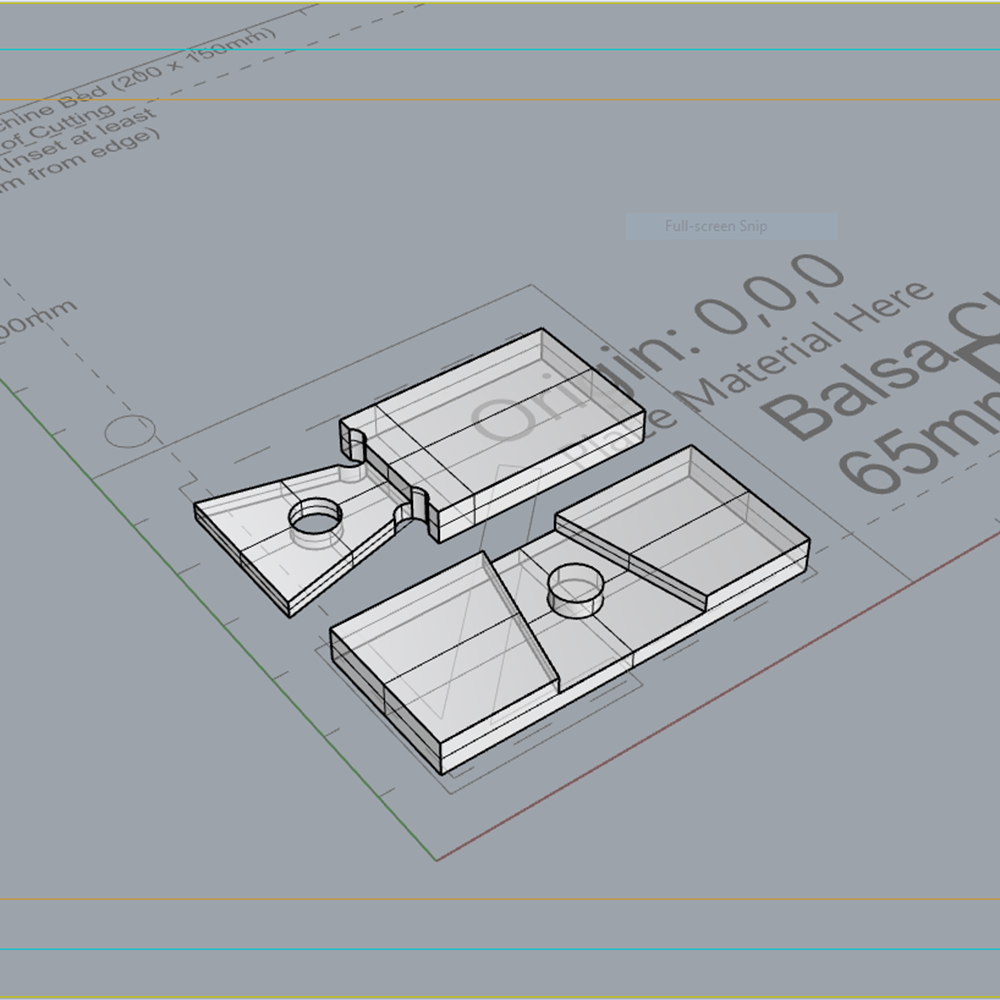

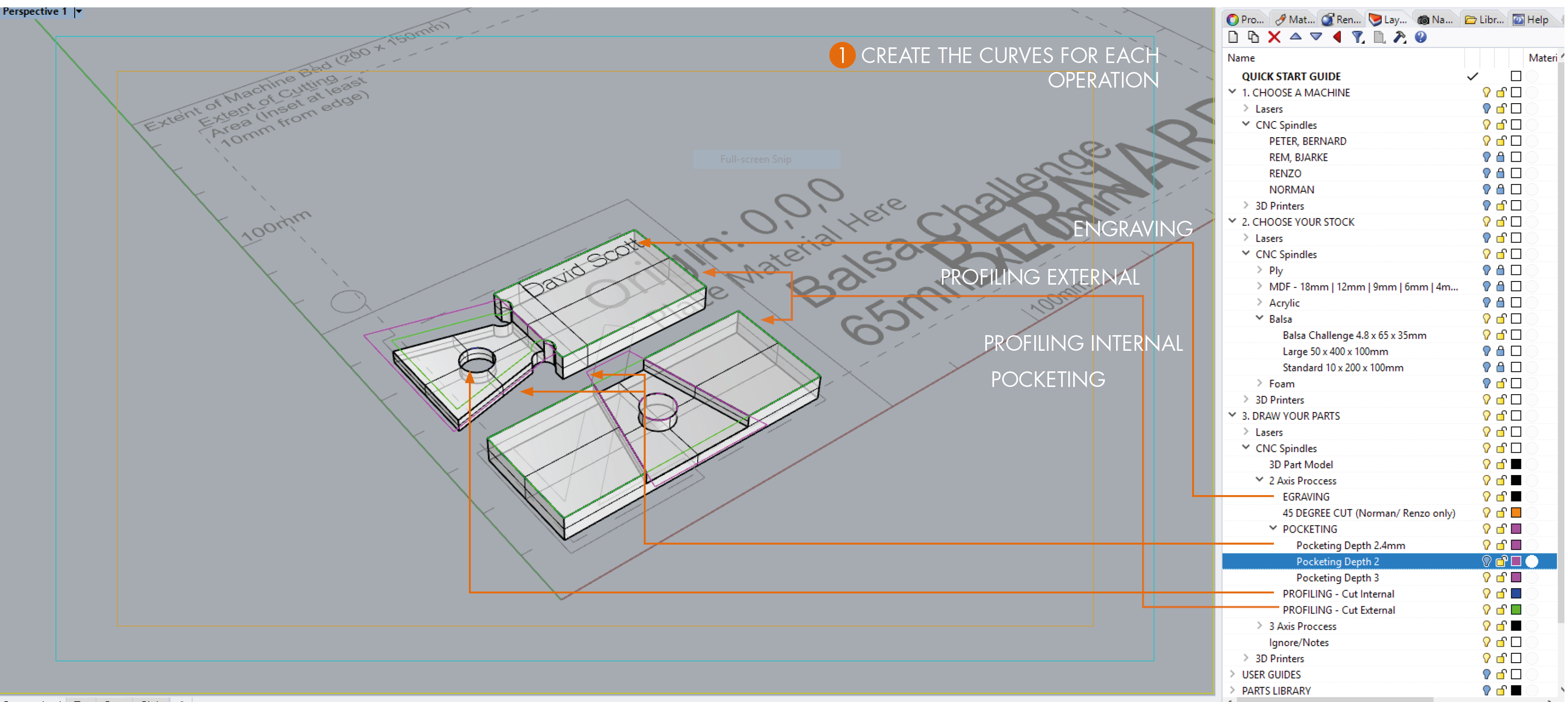

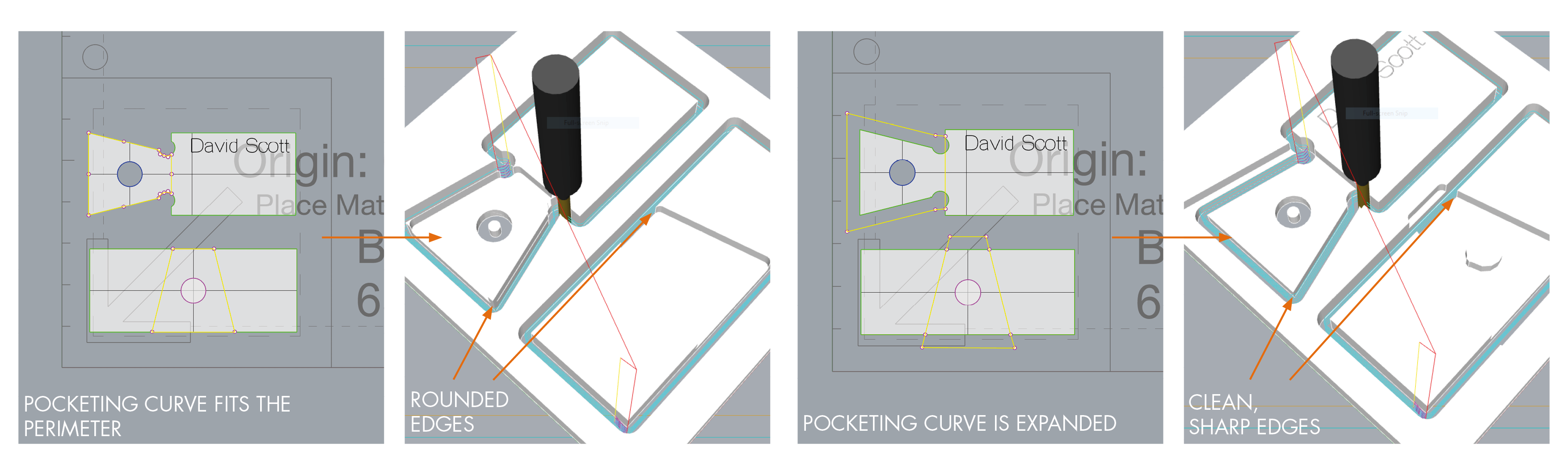

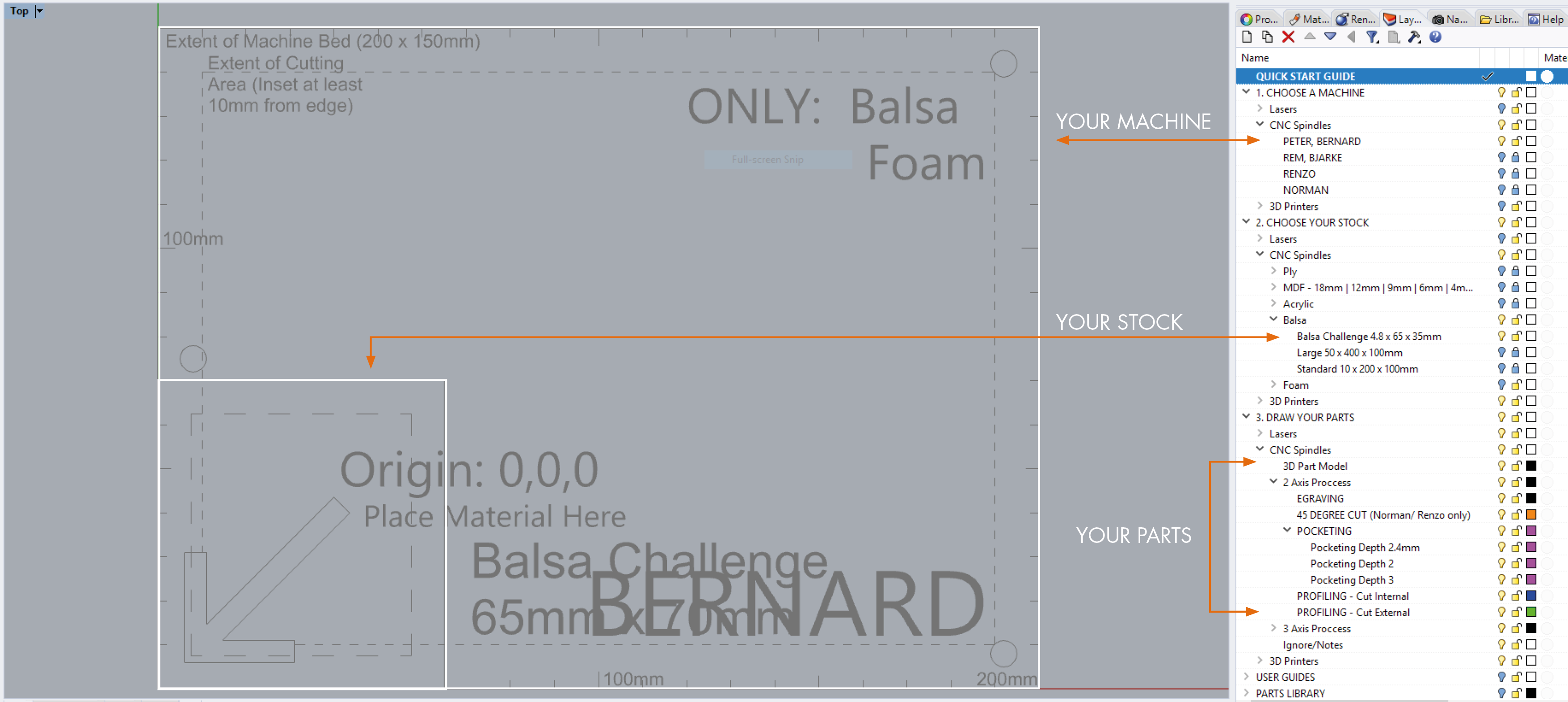

Download the template file and model what you want to machine.

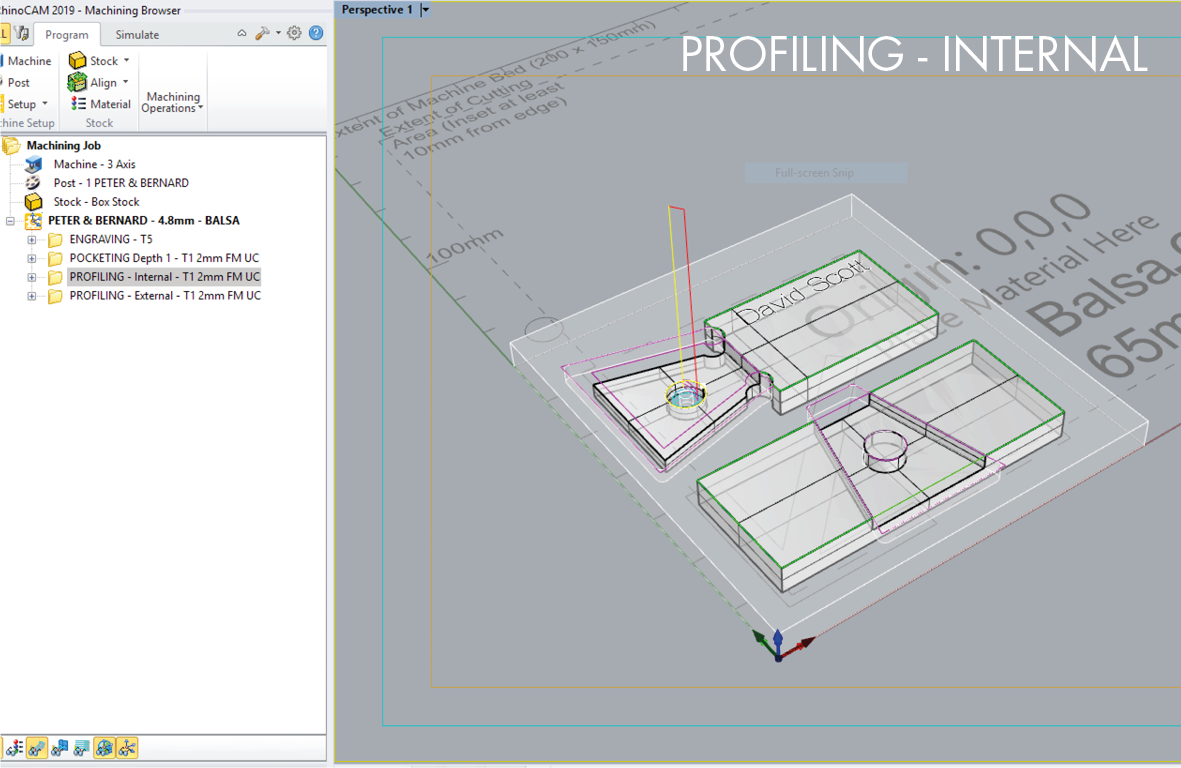

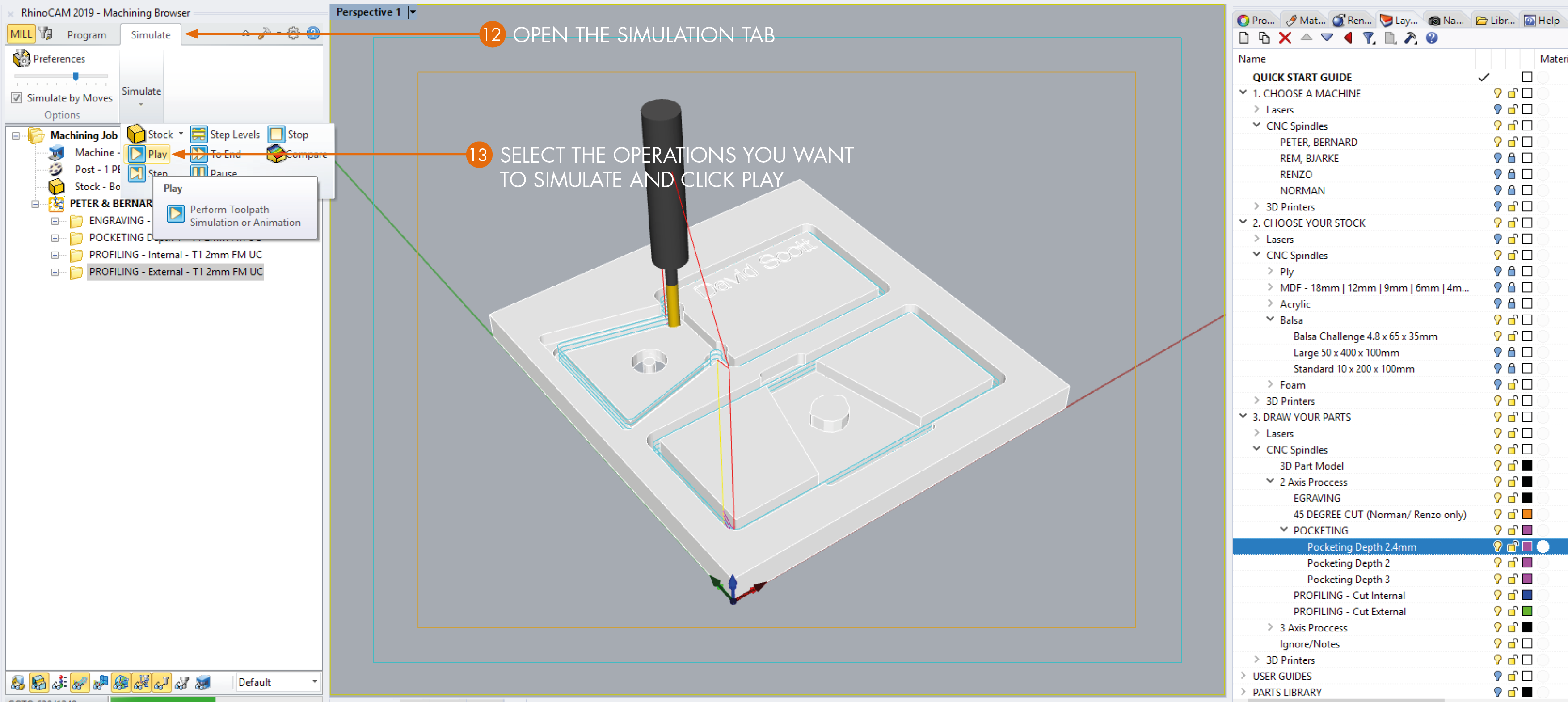

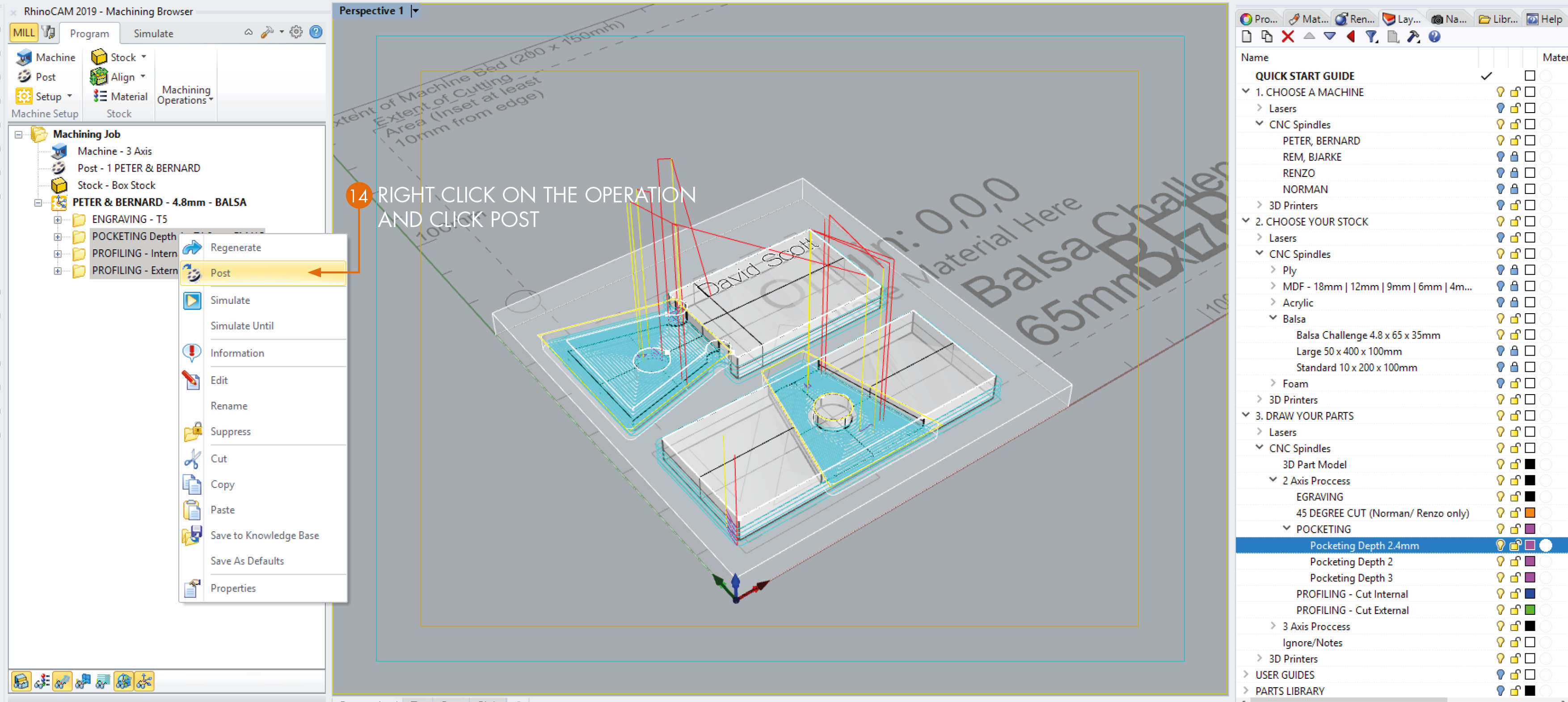

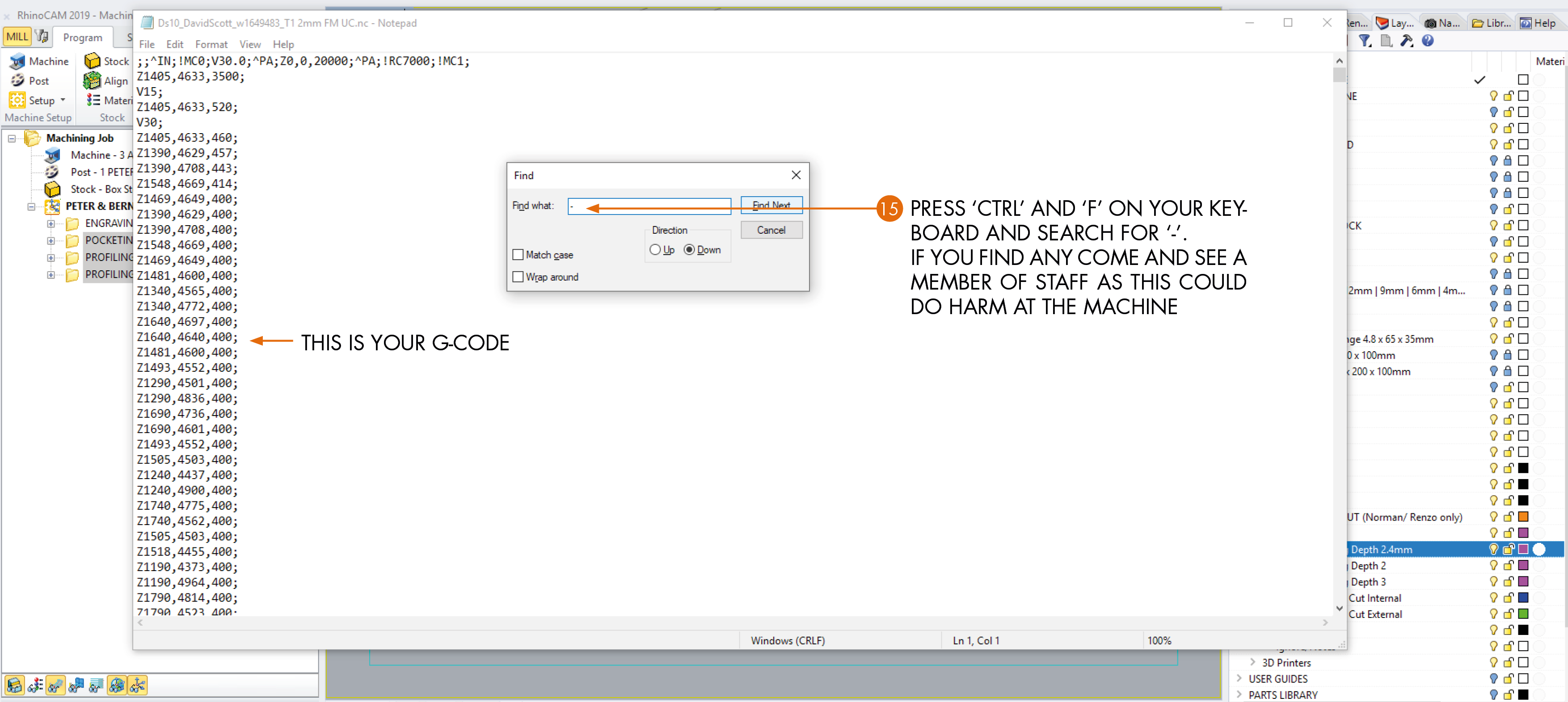

3. Program

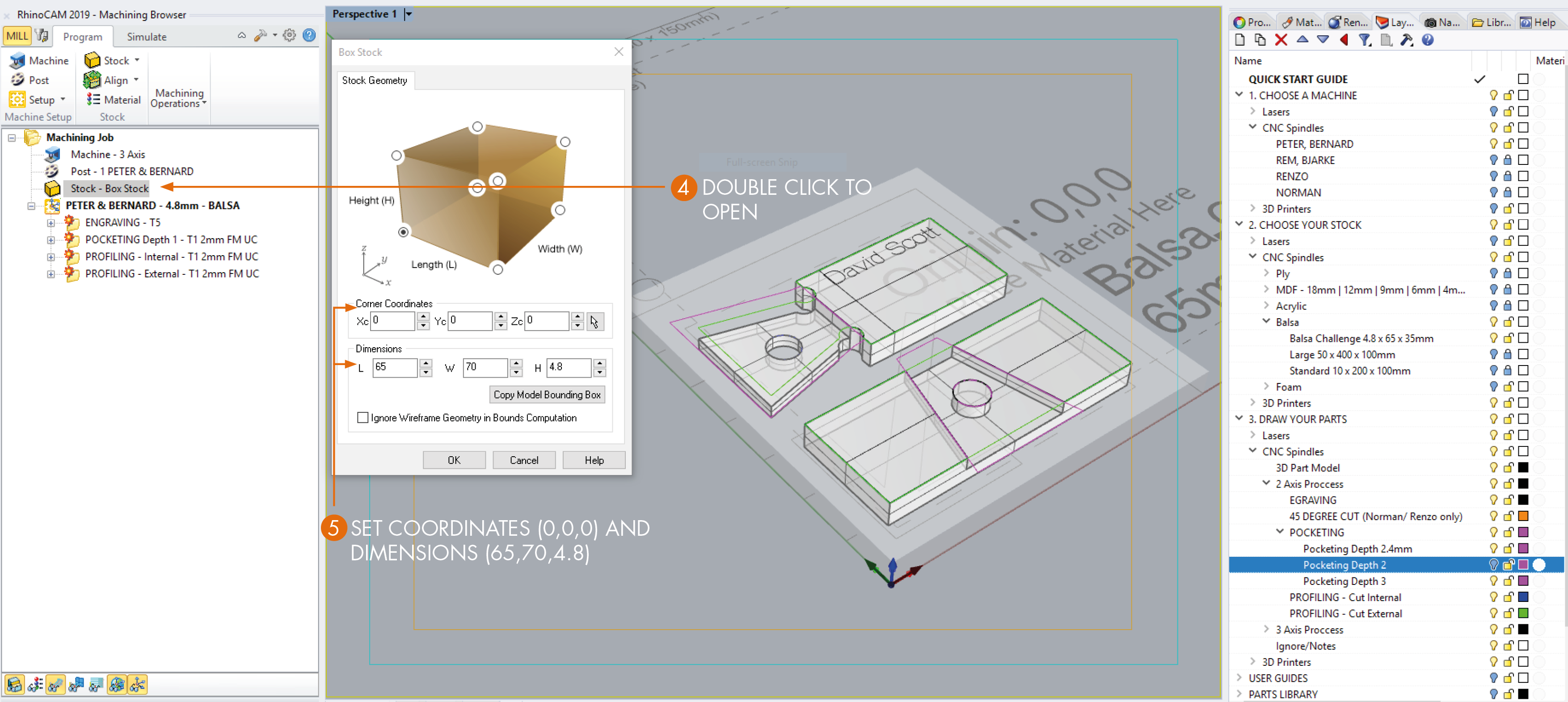

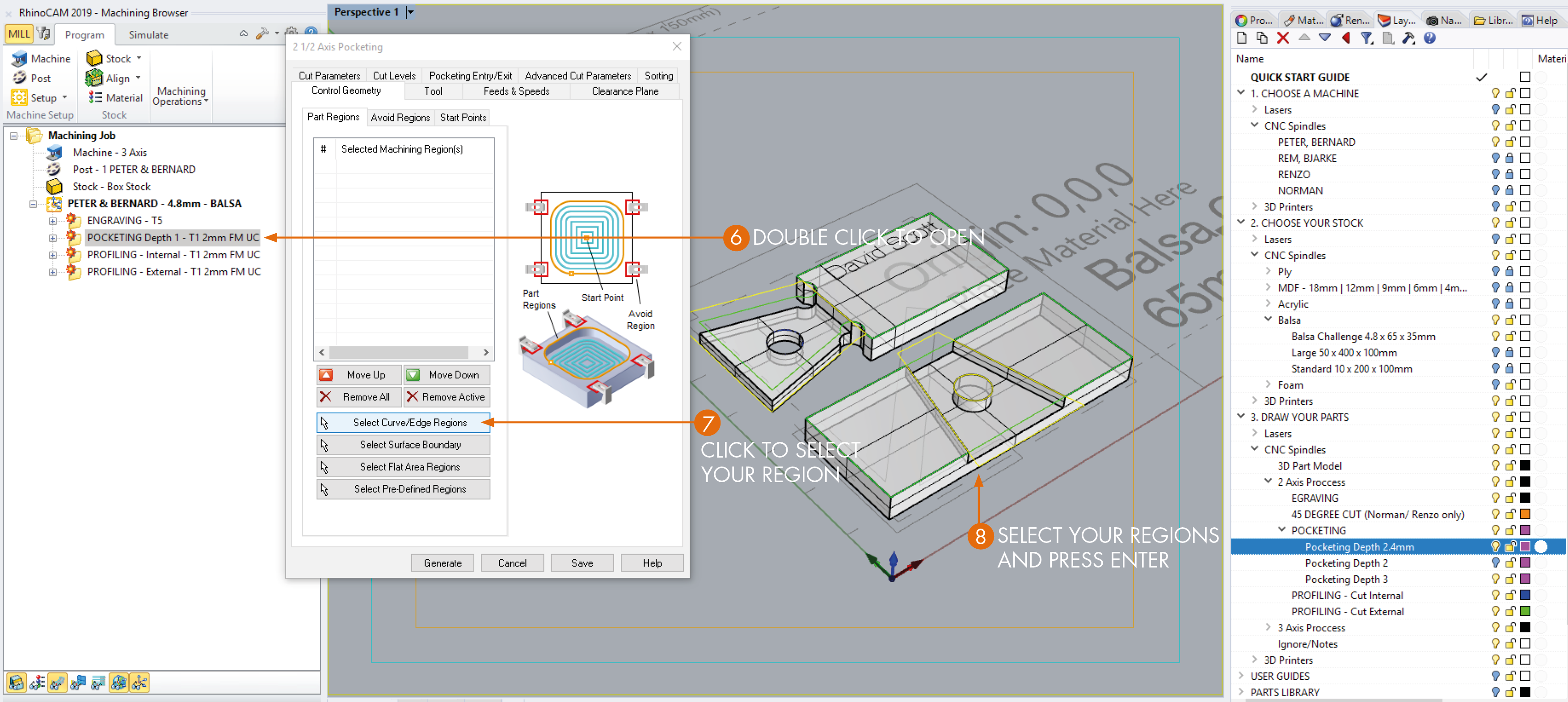

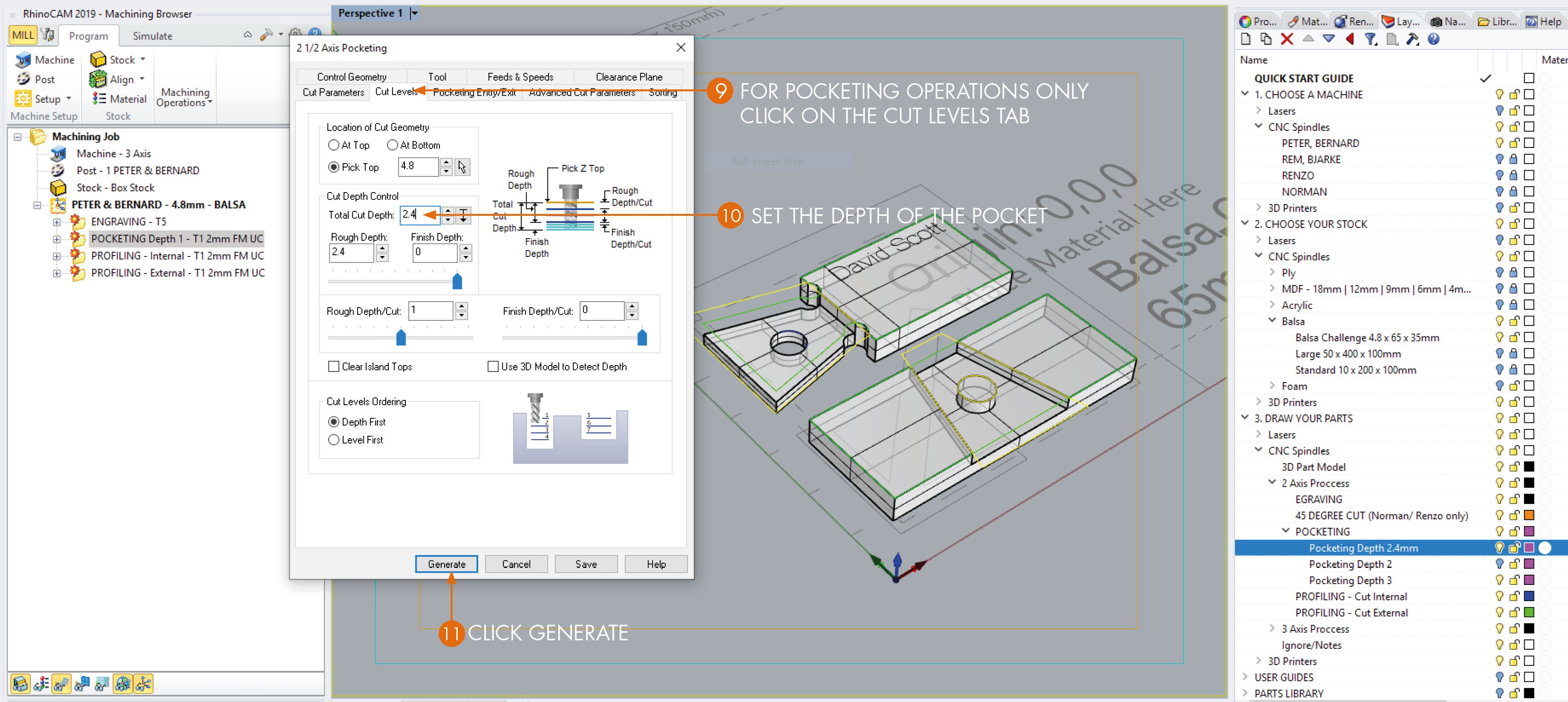

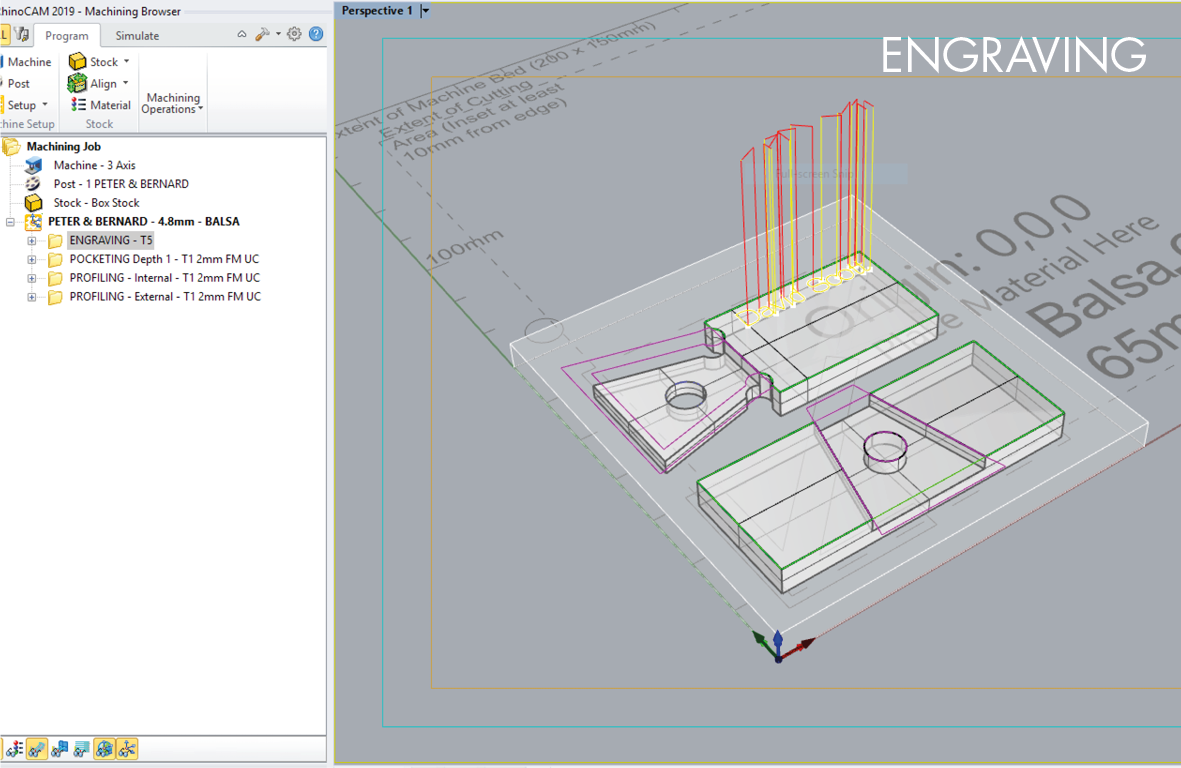

Book into the CAM Lab to program your CAD models in Rhino CAM.

4. Book

If you want to use the Mini Mills go ahead and book. If you want to use the CNC Routers send your file for checking and once approved you can book.

5. Come in for your booked slot

Come in and use the CNC to machine your work.

CNC ESSENTIALS

HERE'S THE THEORY

If you want to progress further please register or login first!

If this button is greyed out then your Balsa challenge has not yet been approved. We aim to contact you with 24 hours of submitting your Balsa challenge. Please be patient.

If you are not able to book a slot (greyed out button) and you have completed your CNC Essentials last term or earlier, please email (Admin@FabricationLab.London) the Lab to get your record updated.

If you are not able to book a slot (greyed out button) and you have completed your CNC Essentials last term or earlier, please email (Admin@FabricationLab.London) the Lab to get your record updated.

1. Create your geometry at home.

You can download a free 90 day trail of Rhino. You will need to have it prepared in the Rhino template before you come to program it.

2. Book your Cam Lab computer

Once you have finished drawing what you want to fabricate book your CAM Computer

Currently due to reduced capacity we can only offer use of the CAM Lab for prcessing Rhino CAM files.

Please log in to book.

ADVANTAGES

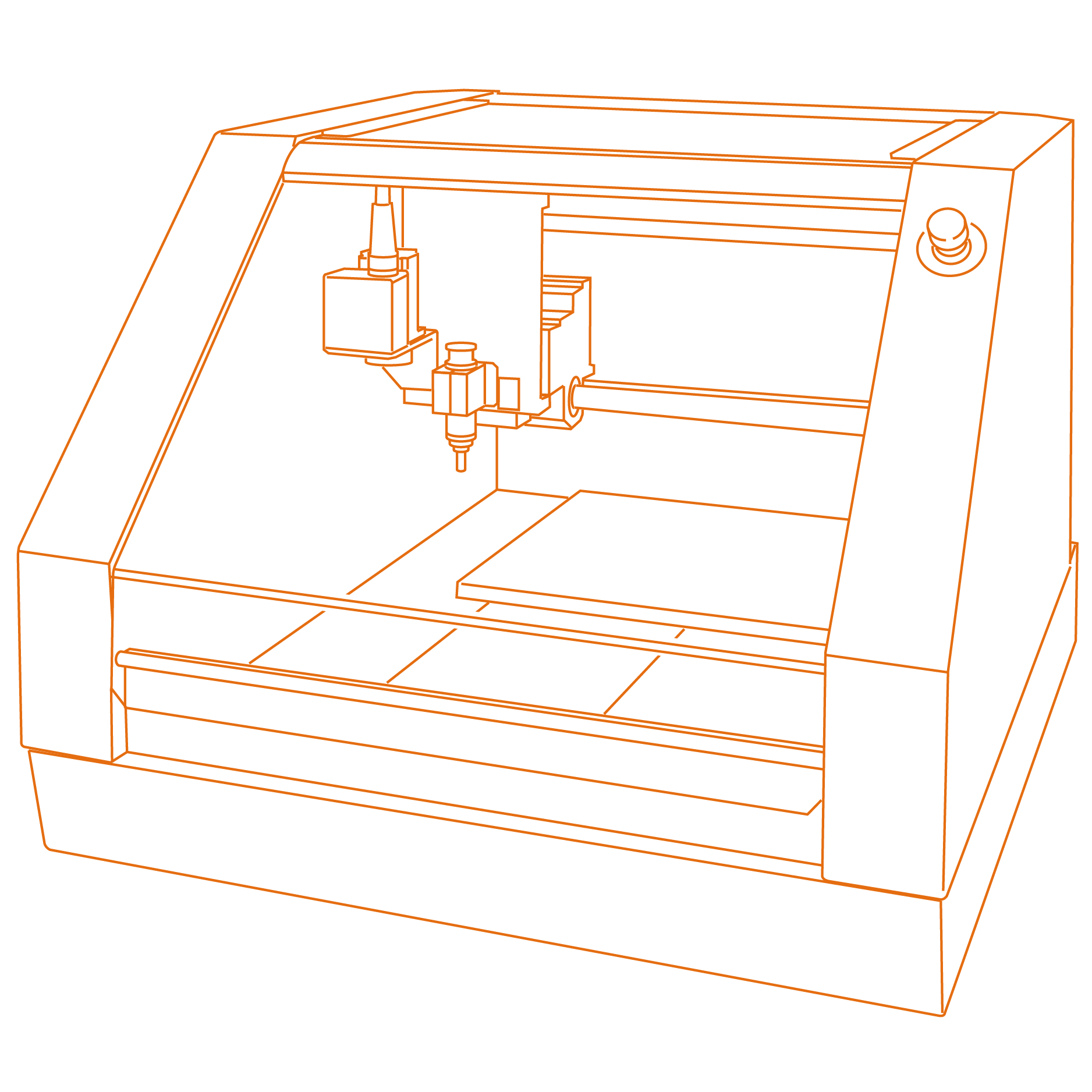

A fast, easy to use CNC Mill. Will machine medium and high density foam to be uses as component parts or molds. Also good for flipping the stock for machining both sides.

DISADVANTAGES

Smaller bed size than the CNC routers. Only machines foam.

£3/h

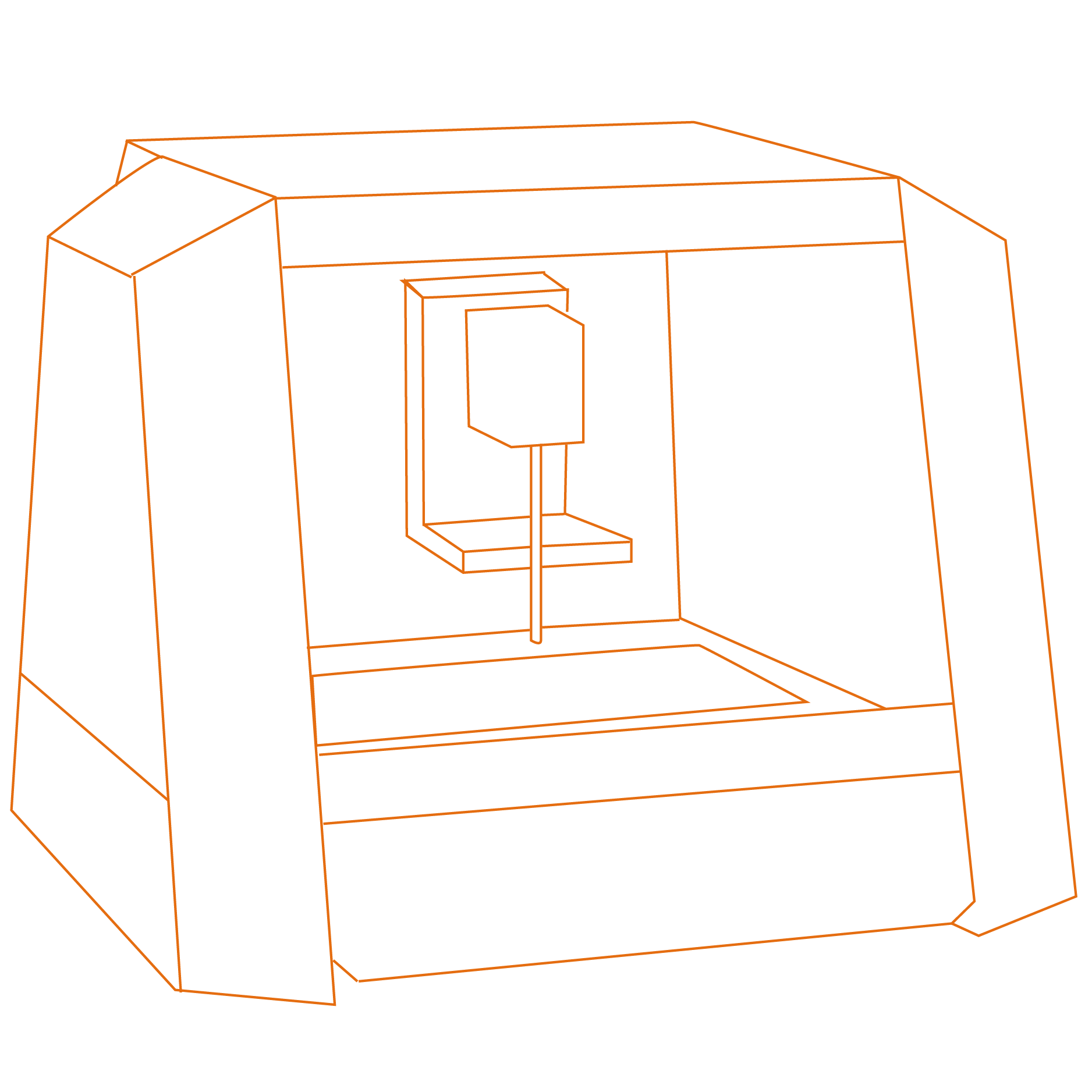

ADVANTAGES

Our lowest price CNC. Will machine medium density foam (Blue and Cream, not Orange foam). Good for machining highly detailed designs. Fitted with our smallest tool (2mm Flat Mill)

DISADVANTAGES

Will only machine Blue and Cream foam. A small bed.

£2/h

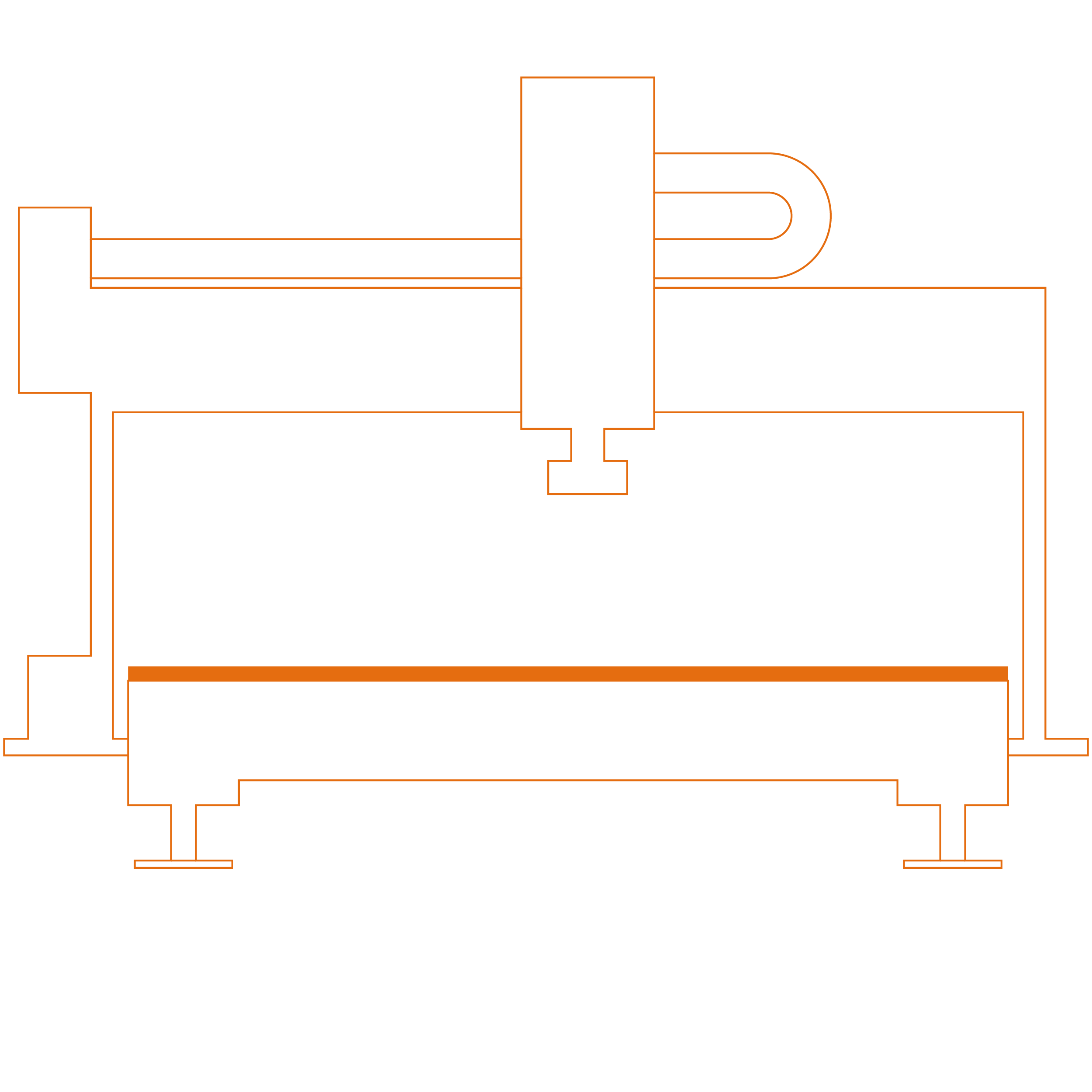

ADVANTAGES

A Powerful CNC Router capable of cutting foam up to 1220 x 1200 x 50. Good for machining context models.

DISADVANTAGES

There are few disadvantages when cutting foam. Unlike normal it has a manual tool change.So jobs that require lots of tool changes can be slow.

£5/h

TO BOOK, EMAIL e.lancaster1@westminster.ac.uk YOUR RHINO FILE AND NC CODE FOR CHECKING. WE WILL BOOK YOU IN.

ADVANTAGES

Our largest CNC. Capable of cutting Plywood, MDF, foam and Acrylic.

DISADVANTAGES

A popular choice of with a que.

£5/h

TO BOOK, EMAIL e.lancaster1@westminster.ac.uk YOUR RHINO FILE AND NC CODE FOR CHECKING. WE WILL BOOK YOU IN.