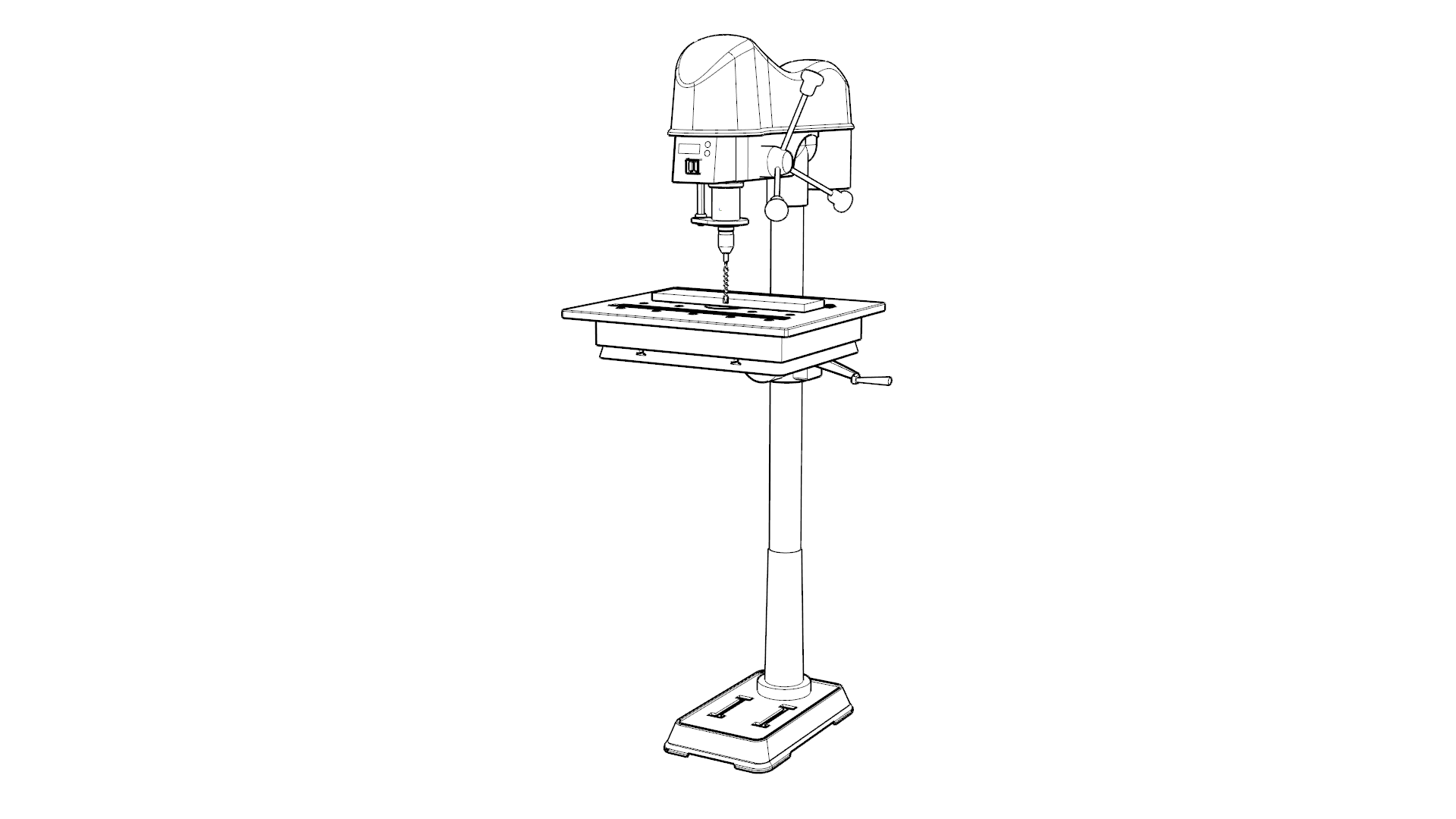

MACHINE

DRILL PRESS

LOCATION

WOODSHOP

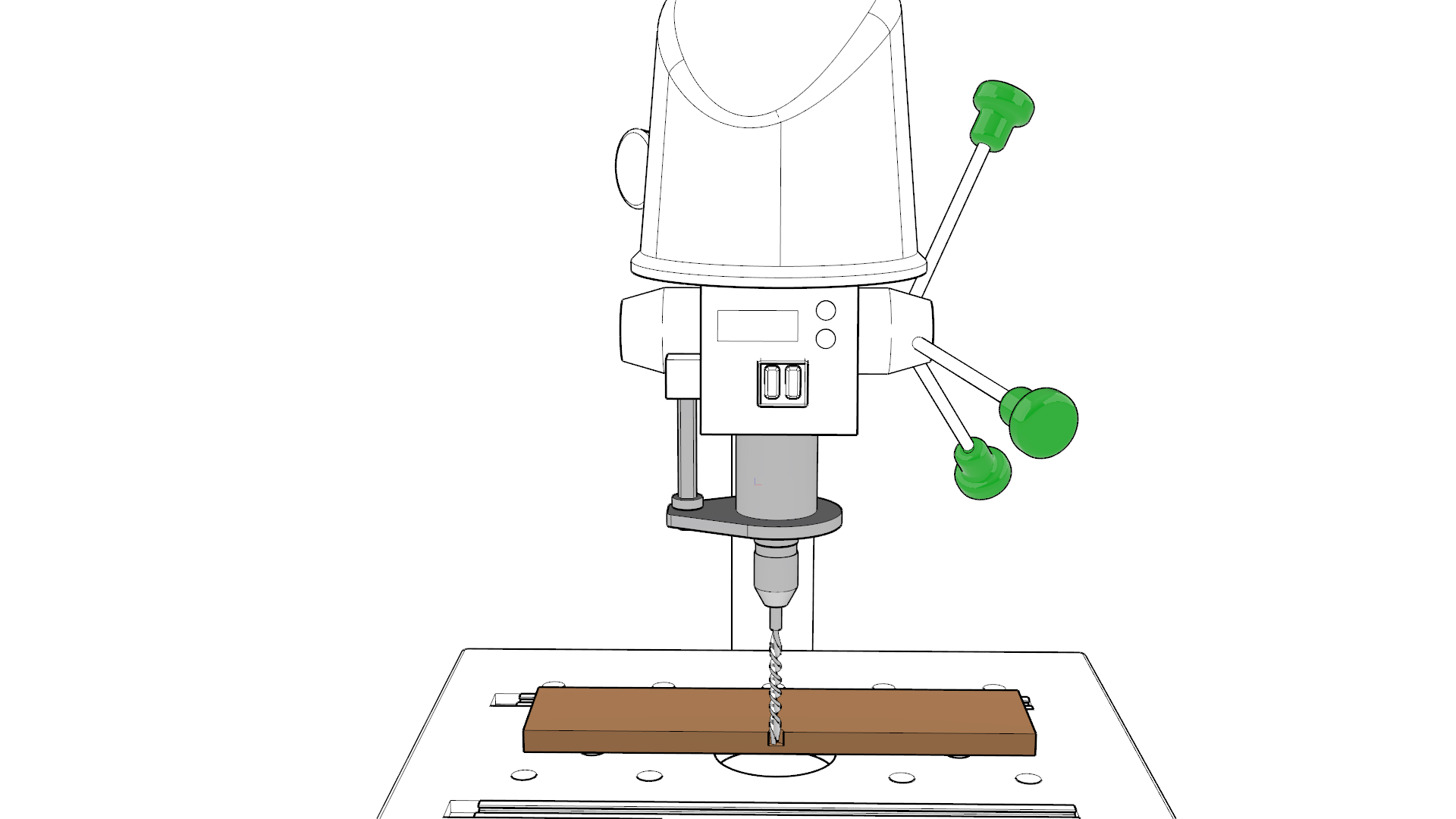

BASIC OPERATIONS

DRILL VERTICAL HOLES

SIZES

1MM - 100MM

MANDATORY REQUIREMENTS

COMPLETION OF WOOD ESSENTIALS

MATERIALS

SOFTWOODS, PLYWOOD, MDF, FORES COLOUR

NO METALS OR PLASTICS

HAZARDS

ENTANGLEMENT

COLLISION

DUST

REMEMBER

ALWAYS CLLAMP YOUR STOCK MATERIAL

ALWAYS VACUUM AFTWARDS

Hazards

Materials